A common question we get asked particularly from those setting up their labelling solution is regarding our different label types. What exactly is the difference between thermal direct - or direct thermal as it is also known, the terms are interchangeable - and thermal transfer labels?

The difference is how information - such as product name, delivery address, SKU and the barcode - is printed on the label. The two methods of printing are known as thermal direct printing and thermal transfer printing.

THERMAL DIRECT PRINTING

The process of thermal direct printing involves the application of heat to the label, done by direct contact of the thermal printhead. Thermal direct labels are made with a special paper substrate that has a heat sensitive dye within, causing a change of colour and in turn information to appear.

View our selection of Direct Thermal Printers.

Just as a side note, the printhead - used in both thermal direct and thermal transfer printing - contains heating elements that act like pixels in a way. As print instructions are sent to the printer, those instructions then cause a range of these "pixels" to heat up. This also relates to a printers DPI (dots per inch) rating.

THERMAL TRANSFER PRINTING

The process of thermal transfer printing is similar to thermal direct printing, in that a thermal printhead is used. However rather than the printhead having direct contact with label, a ribbon is used in between the printhead and the label, causing the ink (a form of wax and/or resin, which we'll cover later) from the ribbon to be transferred to the label.

View our selection of Thermal Transfer Printers.

The easiest way to remember this is thermal direct involves printing "direct" onto the label, whereas thermal transfer involves the "transfer" of ink to the label.

WHAT ARE THE USES OF EACH TYPE?

Choosing whether to use thermal direct or thermal transfer labels and printers comes down primarily to the label life requirements, but there are other considerations which we will touch on.

THERMAL DIRECT LABELS

Essentially, thermal direct labels are suited to shorter-term labelling purposes. The print will fade and the label material will darken over time, especially so if exposed to conditions like heat and sunlight, or to a fair amount of handling/contact. However labels on items stored in cool and/or shaded environments such as warehouses or storerooms will have decent longevity of many months.

And as thermal direct printing is done without ribbon, the machines are simpler to use and maintain and in turn more durable. No ribbon also means one less consumable to be keeping track of.

Common uses of thermal direct labels include receipts, shipping labels, ticketing, name tags, warehousing pick labels.

View our standard range of Direct Thermal Labels.

THERMAL TRANSFER LABELS

Thermal transfer labels come in a wider variety of material than direct thermal, ranging from paper to various synthetics with increasing levels of durability and resistance.

The ink from the ribbon is not only transferred, it is absorbed into the label itself. This leads to a higher quality and longer lasting image, and so is suited to a greater range of purposes, such as long life asset tracking, laboratory specimen labels exposed to chemicals, tiny print labels, warehouse rack labels, permanent ID labels, etc.

It is also worth noting that as the printhead is in contact with ribbon rather than the label itself, this will generally result in a longer life of the printhead.

View our standard range of Thermal Transfer Labels.

As for the thermal ribbon, there are three main types used. These are wax, resin, and a combination of wax-resin. Wax-resin is the most common type, and has a reasonable level of durability. Wax is cheaper but is less durable. Resin is the most expensive, but has the highest durability and resistance to chemicals.

View our Thermal Ribbons.

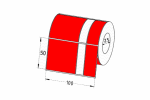

Just a note, labels and ribbons come in different configurations, such as core size, outer diameter, and with ribbon there is also variations on which side of the ribbon the ink is on. Always check the printer specifications to ensure the consumables are compatible.

We hope this has been helpful for you, or at least informative! If you would like to read more about thermal printing, we recommend SATO America's whitepaper Thermal Transfer vs. Direct Thermal: Five Key Considerations. SATO invented thermal direct printing, and created the world's first thermal transfer printer in 1981. This whitepaper goes into much more detail, and if you're still not sure about which path to take then we highly recommend giving it a look. And of course you can contact us with any questions you may have.